Quality assurance that saves lives

Optimize your fastening processes with QST – the software solution for efficient quality assurance and tool testing

Whether screwing, riveting, or crimping – QST ensures precise testing and documentation. Structured task lists streamline inspection planning, while tamper-proof documentation and reliable tool checks maximize process security. Protect your products and minimize liability risks with QST.

DO THESE PROBLEMS SOUND FAMILIAR TO YOU?

Quality problems due to inadequate testing processes

QST optimizes your test planning and execution so that your series production consistently delivers the highest quality.

Lack of documentation and transparency

With QST, you can track every bolted joint and achieve complete transparency and traceability.

Insufficient traceability of quality data

QST guarantees complete historization – all master data can be retrieved for years.

Uncertainty in product liability

With QST you are on the safe side – all data is stored in an audit-proof and legally compliant manner.

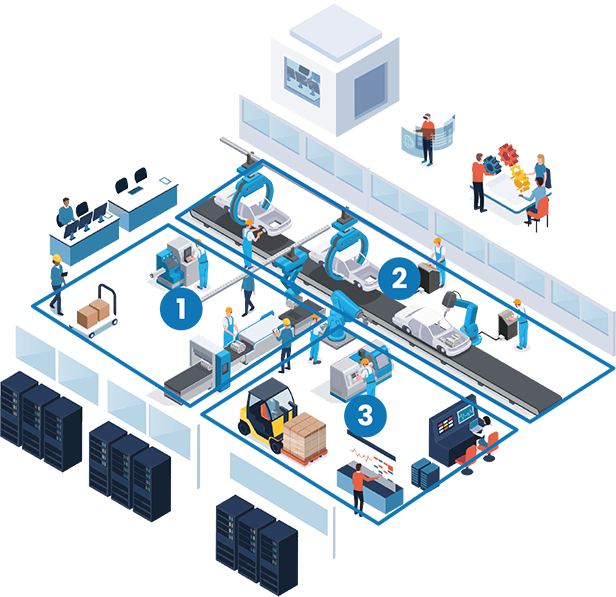

Test planning that ensures quality.

Maintain an overview of all inspection processes – from tool inspection to rotating tool inspection to process inspection. Efficiently planned, securely documented, reliably executed. With QST, you can ensure that all connection technologies such as screws, rivets and crimping meet the highest quality requirements.

1. Tool Testing

Use the test bench to ensure that your hand tools are working optimally before they are integrated into the production process.

2. Rotating Tool Testing

Precise measurement of torque and angle of rotation for maximum quality – even for permanently installed tools, can be tested regardless of location.

3. Process Control

Ensure quality – reliably check after production whether all requirements have been met.

The advantages of QST at a glance

Manufacturer independence

Our solution is 100% manufacturer-neutral and optimally adapted to all systems – for maximum compatibility, flexibility and integration.

Reduce costs

Maximize your efficiency and reduce operating costs through precise tool inspections, optimized processes and the free choice of cost-effective test equipment.

Avoid recalls

Through precise quality controls and compliance with the highest standards, you prevent potential sources of error that could lead to expensive recalls.

Predictive Maintenance

Use predictive maintenance to avoid breakdowns, extend the service life of your machines and minimize unplanned downtimes through proactive checks and service.

High product quality

Continuous monitoring and precise tool checks guarantee the highest product quality and reduce sources of error.

Complete documentation

Our solution offers complete, traceable documentation and audit-proof archiving – for maximum transparency and legal protection.

OUR QST SOLUTION FOR YOUR APPLICATION

X Options for efficiently organizing your quality assurance

Quality Manager

Optimized quality assurance for smooth processes

Reduce risks and increase the efficiency of your quality processes with QST. Our solution helps you to avoid errors in production through precise tool and process monitoring. Minimize the effort required for inspection planning and improve the quality of your products – all with maximum process reliability. This allows you to reduce costs and increase the efficiency of your quality management at the same time.

Quality Officer

Secure data, available at all times

Avoid uncertainties and compliance problems with QST. Our solution ensures audit-proof and seamless documentation of your quality data so that you can access all information at any time. You can easily meet product liability requirements and ensure that your data is always legally compliant and audit-ready – without any additional effort.

Those who use QST produce more reliably

From the quality gap to a reliable solution: leading companies rely on QST for precise quality assurance

Wide range of applications for QST

QST is a powerful software solution for companies from various industries. Our solution helps you to efficiently organize quality inspections while meeting product liability and documentation requirements.

Automotive

In the automotive industry, where maximum precision and quality are required, QST helps to continuously monitor and improve the quality of production processes.

Aviation & Aerospace

For the aviation industry, QST ensures that all production and testing processes meet the highest safety standards and guarantees complete traceability of quality.

Mechanical engineering

Mechanical engineering benefits from QST by enabling efficient tool inspection and monitoring process quality to minimize downtime and ensure product quality.

Railway

In rail technology, QST offers a solution for precisely monitoring the quality of components and processes to ensure the safety and reliability of trains and infrastructure.